Deep Draw Technology

Deep Draw Technology for Metal Manufacturing

Buckeye Shapeform are experts in Deep Draw Metal Fabrication

Buckeye Shapeform is recognized as a leader in deep draw technology for metal forming. Deep draw metal fabrication has many advantages including a cost friendly, reliable alternative to processes like impact and spinning. With deep draw, any industry can benefit from experiencing higher output with lower costs when it comes to metal forming. Deep draw processes provide many benefits to customers including:

Improved accuracy from deep draw: With tight tolerances in the thousandths, deep draw creates highly calibrated products

“Flexible” Hardness: For some products aluminum is better suited than steel. The deep draw process uses aluminum and a uniform grain structure to create a strong product that is ductile, but also reduces vibration. Reducing vibrations is very important for electronics and other technology-based hardware.

More from Less: Aluminum delivers three times the effective product as steel. Steel is often subject to fluctuation in market prices and tariffs.

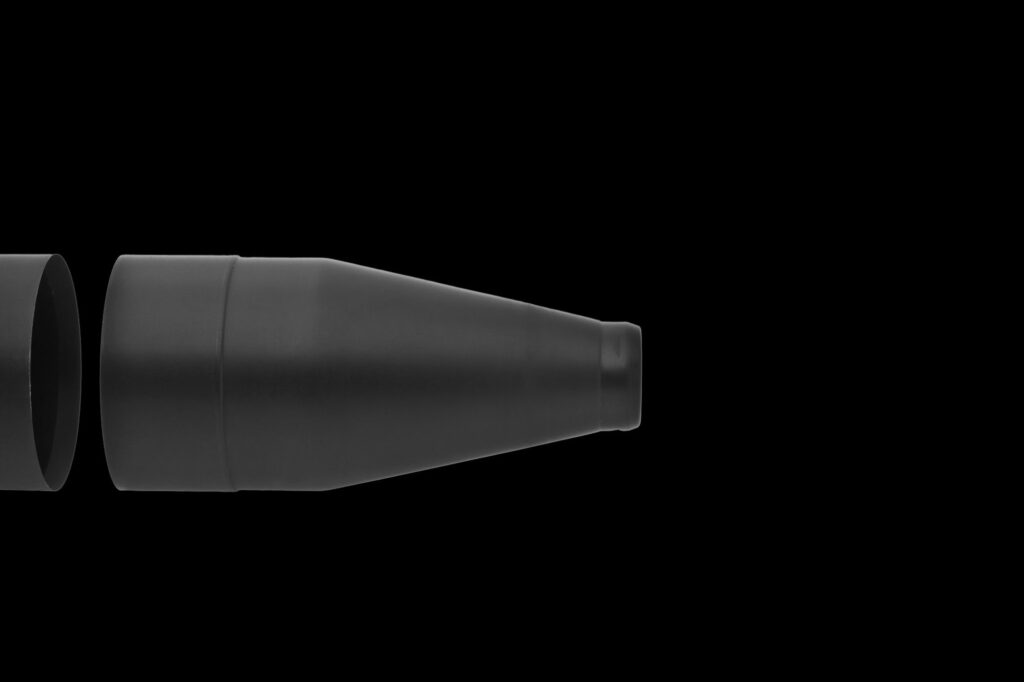

Deep draw technology allows for scalable creation of products that need to be strong but also of minimal weight. If you need metal shaping for seamless parts, rapid cycle times, complex shapes, and more then Buckeye Shapeform deep draw technology can be an asset for mission-critical parts.

“For our rocket launchers, we needed a supplier with expertise in modern fabrication techniques,” said the company’s program manager. “We needed a team that could give us a perfect inner tube every time, without a welded seam, that could withstand the rugged, deadly arena of the battlefield.” -Classified

“Through extensive conversations and multiple visits to Buckeye Shapeform, we knew they had the people and the technological knowhow to help us meet the rigorous fabrication challenges we faced.” -Classified

“Every part of a weapon like the rocket launcher has to be precise, especially the parts involved with protecting the soldier, such as the inner tube. Not only is the end product what we wanted, but the speed and price with which Buckeye Shapeform delivered the product met our expectations.” -Classified